Custom solutions

The key drivers for automotive OEMs across the globe are to make cleaner and cleaner, and more and more fuel-efficient vehicles. Within this context, the automotive industry faces enormous challenges — including among other things — the use of innovative drive concepts; lightweight construction; cost efficiency; and increased functionality. As such, automotive OEMs need to work with adaptable service suppliers that can provide customised solutions for specific applications.

The highest precision metal components are required while attaining increasingly tight tolerances and greater complexity. These consistent requirements play to the strengths of micrometal’s inline reel-to-reel photochemical etching technology, a continuous industrial etching process which economically produces extremely high quantities of thin metal parts.

Advantages and benefits for the automotive industry

- Highly automated manufacturing process – you benefit from high quality products at an economical price

- High degree of freedom in product design – you benefit from a huge range of part design options - you are one step closer to your desired solution

- Stress- and burr-free products – you benefit from fewer post-processing disturbances, which contributes to end-use product integrity and safety

- High reproducibility due to the non-wearing tool and sophisticated manufacturing - you benefit from consistent parts while maintaining tolerances over the complete product life cycle

- Delivery as strip goods – you benefit from successive fully automated further post-processing, which will bring you clear advantages in terms of total costs

- Cleanliness (free of dust, oil and grease) from the line – you benefit from the elimination of additional cleaning processes, which is reflected in the cost-effective parts price

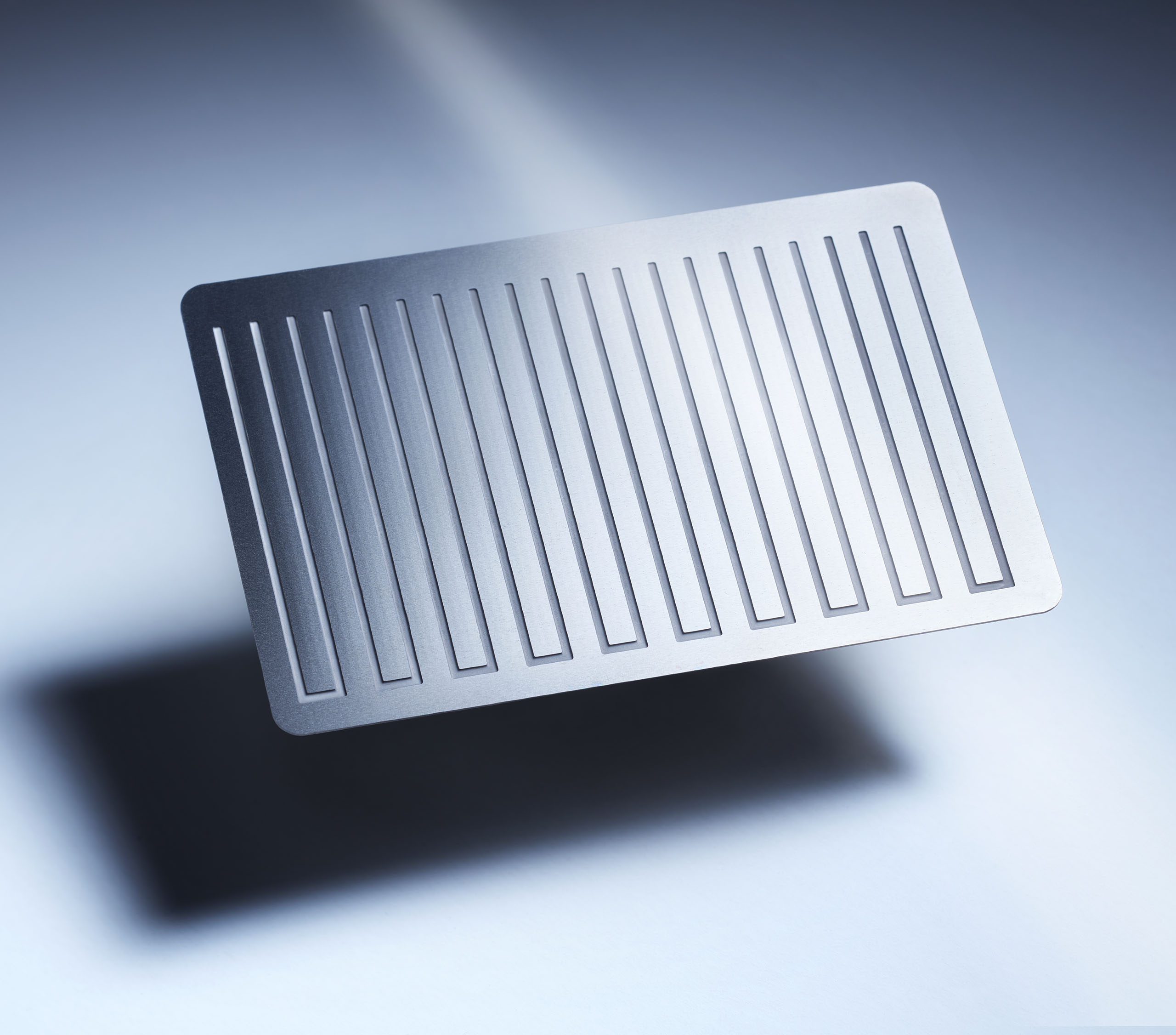

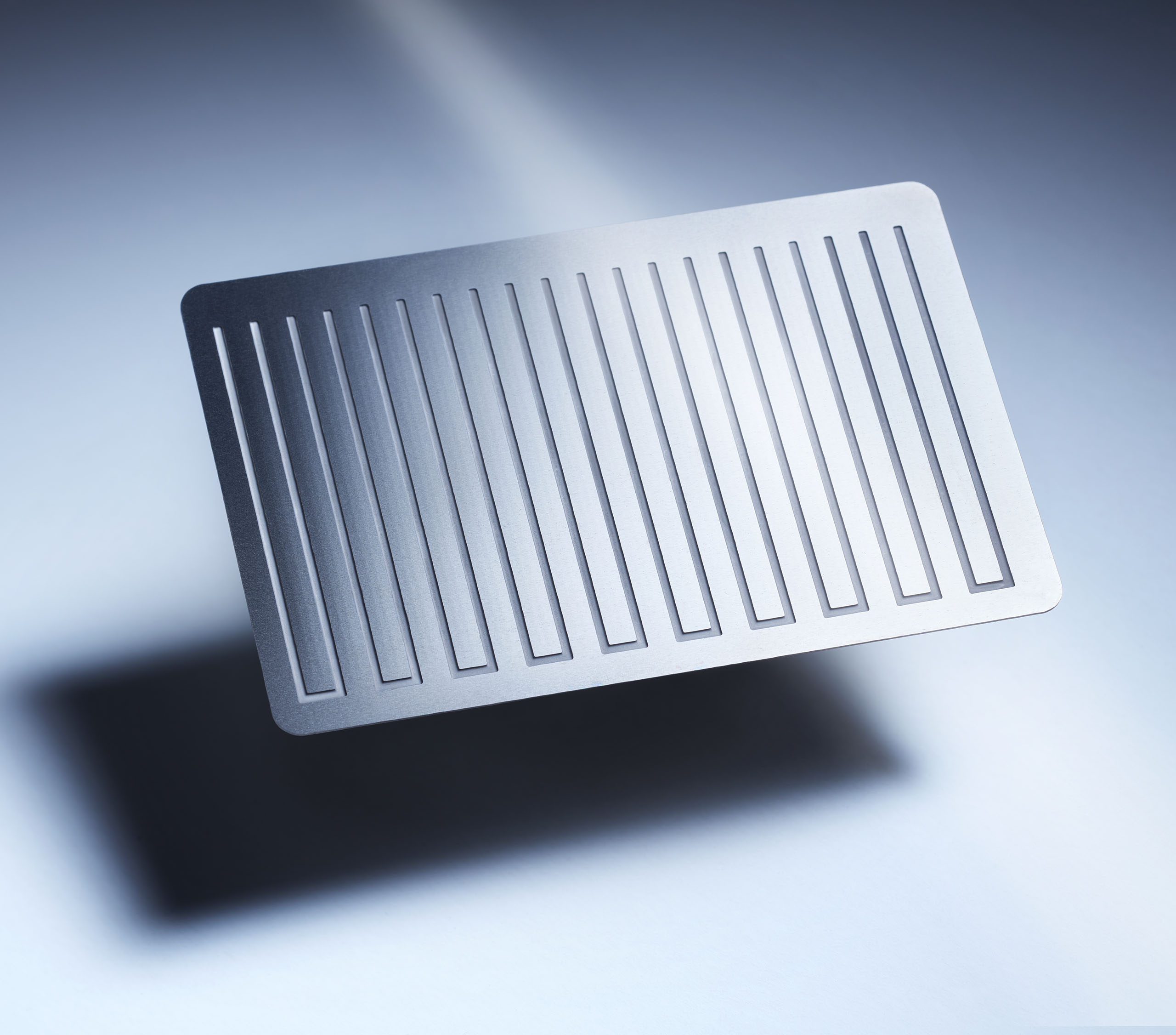

Applications

- Filter and Sieves

- Bipolar fuel cell plates, fuel cells

- Flexures

- Pins for electronics

- Springs

- Functional surfaces

- Automotive interior: loudspeakers, door sills, etc…

Our standards are industry leading

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to IATF 16949, ISO 13485, ISO 9001 and ISO 14001. micrometal combines the infrastructural capacity, level of experience, and strategic focus required to surpass the ever more exacting requirements of automotive OEMs