Chemical etching of stainless steel

The most commonly used metal in photo chemical etching is stainless steel. Its favorable material properties combined with the large number of possible alloys makes stainless steel the metal of choice for many applications in a wide variety of industries.

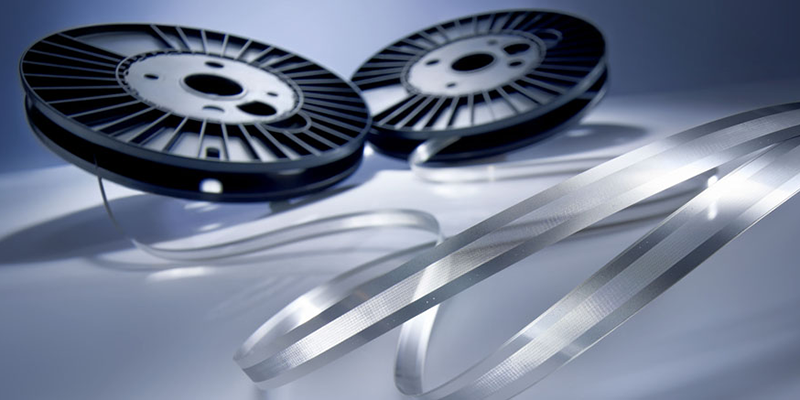

micrometal is manufacturing thin steel parts in worldwide unique precision. Most complex designs and shapes can be realised. The continuous etching line is allowing the economic production of very large volumes.

Large metal selection from stock

Typical examples of stainless steels we etch in our factory:

The thickness of the etched stainless sheets and foils ranges from 25 µm to 2 mm.

- 1.4310 (AISI 301)

- 1.4404 (AISI 316L)

- 1.4301 (AISI 304)

- In addition to the well-known austenitic steels, we etch a variety of ferritic, martensitic (1.4028 Mo/7C27Mo2) or duplex steels, Invar, Alloy 42, ...

The thickness of the etched stainless sheets and foils ranges from 25 µm to 2 mm.

Advantages of the steel etching process

- Burr-free and stress-free metal parts

- Processing of hard or thermally hardened steels

- Material properties remain unchanged

- Easy subsequent industrial processing

- Shorter lead times, move quickly from prototypes to series production

Typical applications for etched steel parts

- Filters, screens, grids, springs, joints and membranes

- Interior trim for automobiles

- EMI/RFI shielding

- Microneedles, blades, lancets, surgical instruments

- Fuel cell plates, bipolar plates,...