A timely and cost-effective technology

The aerospace sector is an extremely competitive market driven by cost controls and strict time-to-market considerations. Aerospace suppliers must therefore be able to shorten product development times, achieve tight and accurate part and component tolerances, ensure compliance with stringent regulatory requirements, and keep costs under control. The aerospace sector is also demanding ever-smaller parts with improved functionality, as there is a push for lighter but always innovative parts that must also be 100% reliable, as they are often used in safety-critical applications.

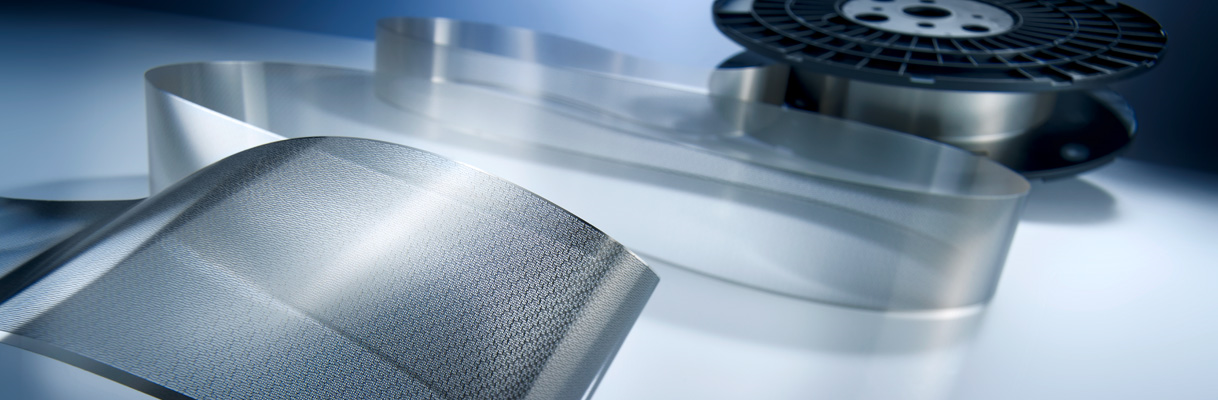

Photochemical metalworking is perfectly suited to applications where small, precise, complex, high-functionality parts are required without burrs or stress-related changes. Furthermore, we can machine strong but lightweight metals such as aluminium and titanium, which are often required in the aerospace sector.

Advantages and benefits for Aerospace

- Machining of metals with high strength-to-weight ratios - you benefit from products that are functional, safe and robust.

- Achieve repeatable ultra-low tolerances - you benefit from accurate parts, from the first part to the millionth, supporting the longevity and quality of your applications.

- Quickly manufacturable and cost-effective tools - you benefit from maximum flexibility to adapt to new conditions.

- Stress- and burr-free products - fewer post-processing disturbances, which contributes to end-use product integrity and safety.

- Machining of the thinnest metals - you benefit from the lightness of parts without sacrificing robustness.

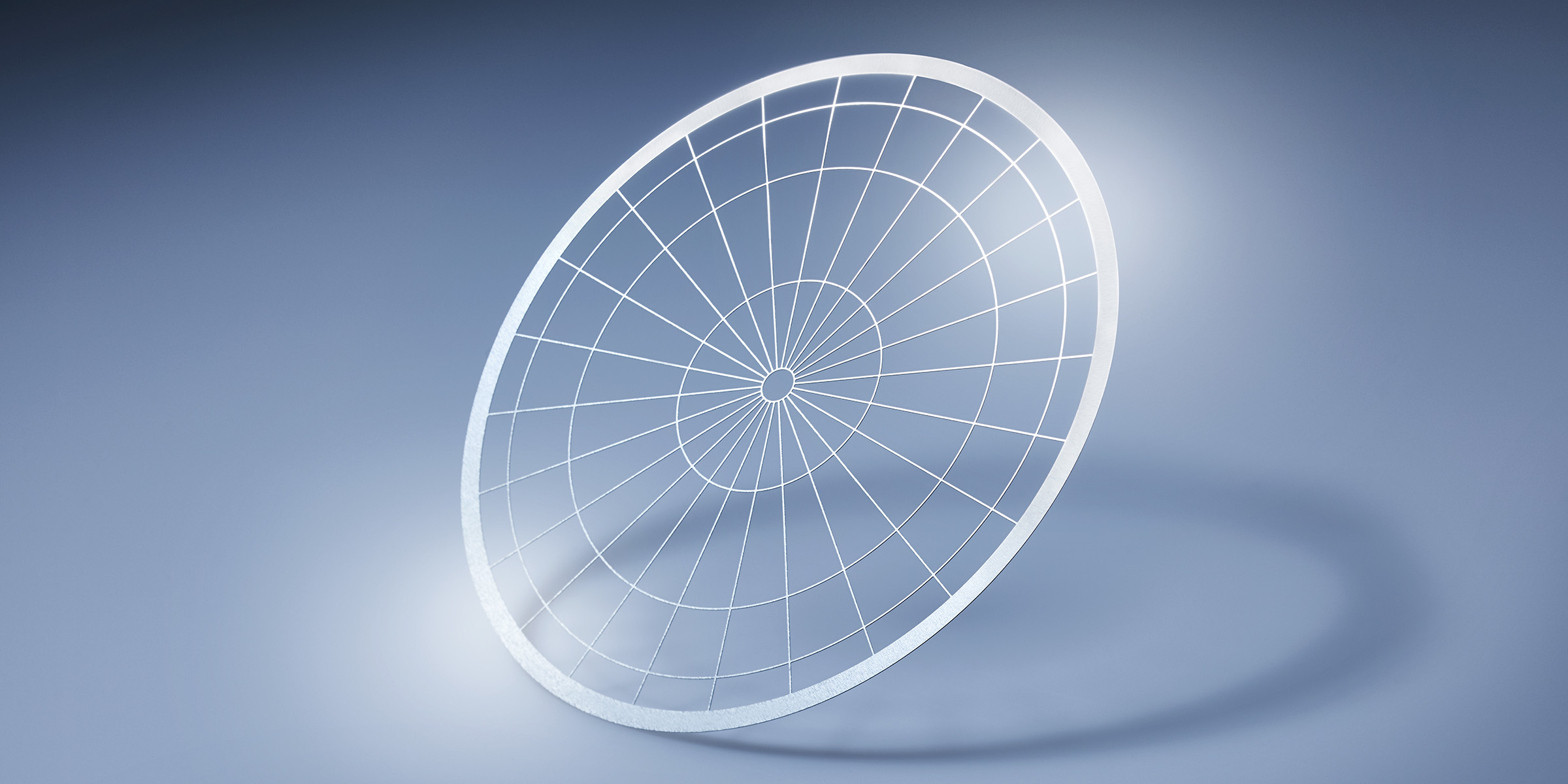

- High design freedom - you benefit from realizing geometric complexity.

Applications

- Heat exchangers

- Grids

- Connectors

- Bending elements

- Springs

- Shielding components

Driving low-cost innovation

The low-cost and easily and quickly adaptable tooling used in the photo-chemical etching process is key to its ability to drive innovation. The process encourages experimentation and innovation in search of an optimal part, as different designs can be created with little additional cost and no significant impact on lead times. Combined this with the photo-chemical etching process’s ability to produce parts with geometric complexity not possible with alternative traditional metal fabrication processes, and the benefits to the aerospace industry are clear.