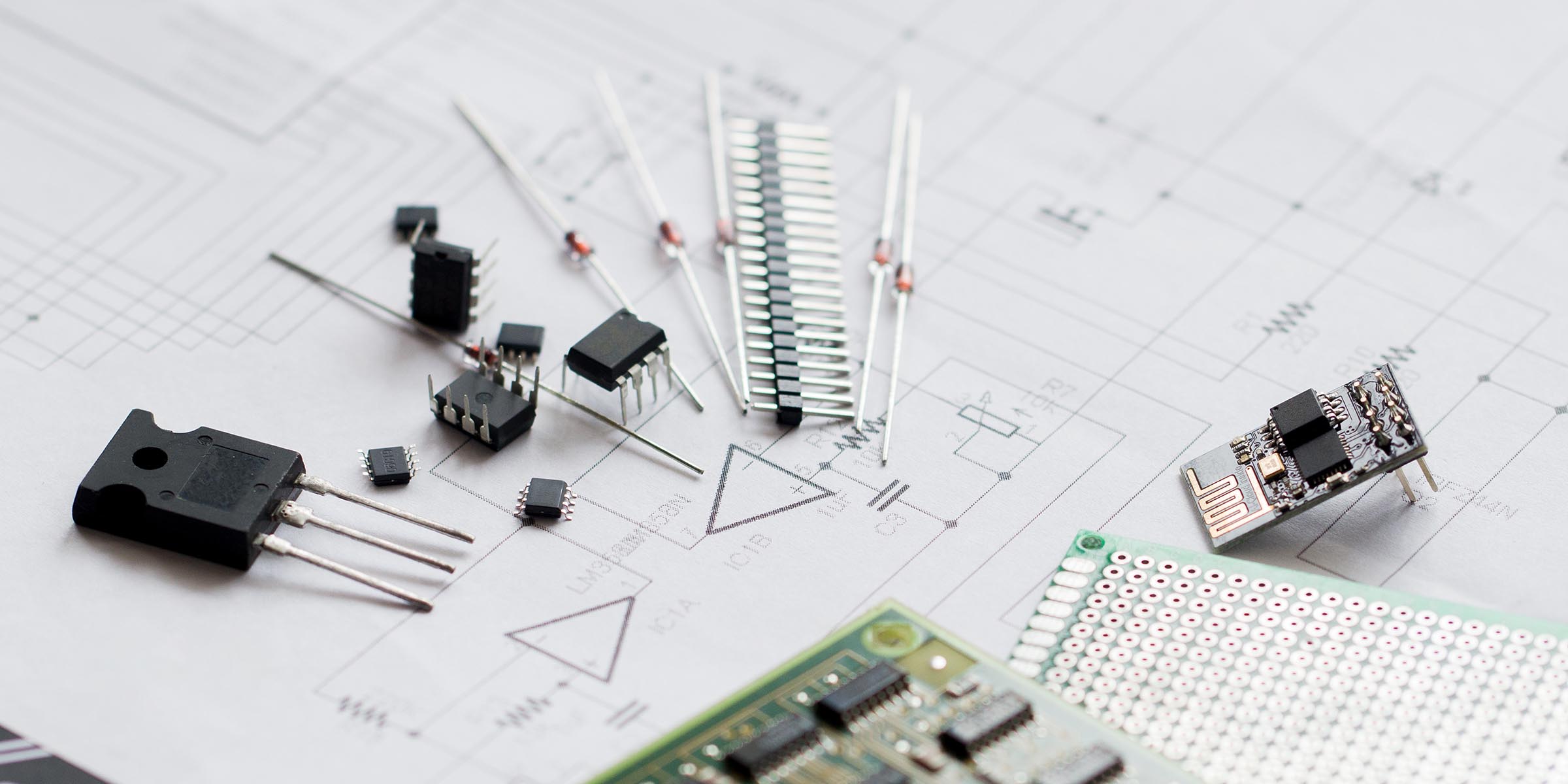

Wet etched precision connectors

Due to electrification in numerous different applications, the demands on plug connections are becoming ever higher. In addition, the demands on the pins are increasing due to the ever smaller size of all electronic components. With our specially developed wet photoresist, we achieve the highest precision while maintaining the tightest tolerances.

The material properties are not affected by the etching process, as there are no thermal or mechanical influences. This helps you and us to etch optimal pins for your SMD components. Further process steps, such as coating to increase conductivity, can be carried out by our reliable suppliers.

Thanks to our cost-effective tool production and our engineering team, we can implement the changes in the rapidly changing electronics industry in the shortest possible time and with the highest efficiency. Through our years of experience and know-how, we produce and develop the pins for your application with you.

Advantages at a glance

- Smallest geometries can be created

- Simplified further processing through etching, predetermined breaking points, 3D geometries, Reel-to-Reel capability

- No change in material properties

- Large variety of materials available

- Design Freedom

- Cost-effective design changes due to low-cost tools

- Economical mass production

Our standards are industry leading

We operate in a world characterized by the tightest tolerances (hundredths of a millimeter), the finest structures, the thinnest metals, and the most complex geometries. We etch customized metal components to the tightest tolerances in large-scale industrial production volumes.

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to ISO 9001, IATF 16949, and ISO 14001.