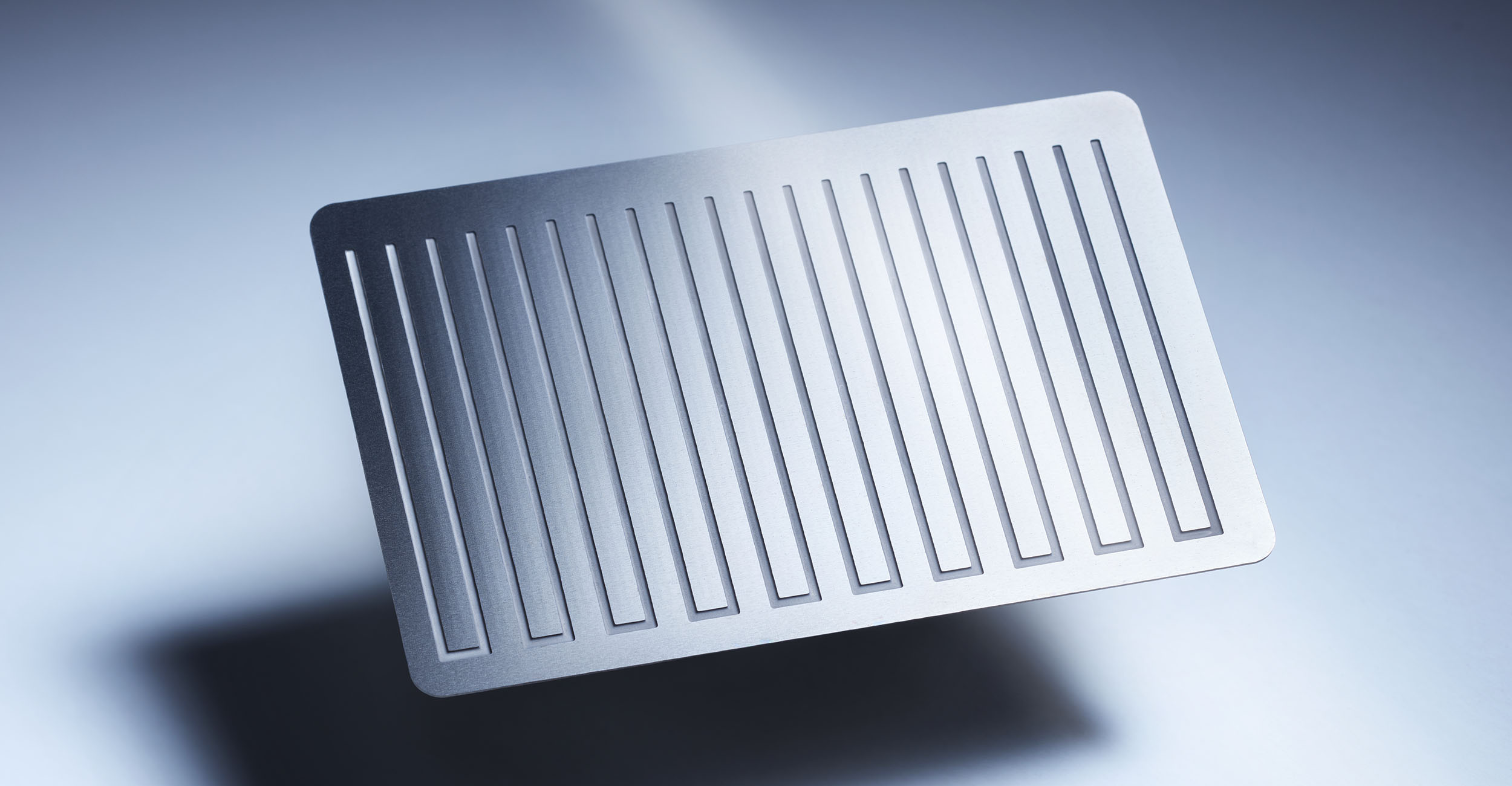

Etched bipolar plates and fuel cells

In order to reduce CO2 emissions from vehicles, various alternative drive systems are being developed. One of them is the fuel cell, which generates energy through a chemical reaction between hydrogen and oxygen, producing only water as a by-product.

Compared to the conventional combustion engine, the fuel cell has much higher requirements for the compression and supply of air. Air must be completely particle-free at a constant pressure level in order to increase the longevity of the sensitive fuel cell.

Thanks to our precision and the ability to etch the finest geometries, we can produce metal filters that mean you no longer have to worry about particles in the fuel cell.

Advantages at a glance

Your advantages at a glance:

- Realization of complex designs (channel structures)

- Cost-effective tool production/design iterations

- Burr-free, stress-free, clean and flat parts

- Machining of thick starting materials and thinning them out

- Channels with a depth of 325 µm in 400 µm material

- Wide variety of metal grades

Our standards are industry leading

We operate in a world characterized by the tightest tolerances (hundredths of a millimeter), the finest structures, the thinnest metals, and the most complex geometries. We etch customized metal components to the tightest tolerances in large-scale industrial production volumes.

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to ISO 13485, IATF 16949, ISO 9001 and ISO 14001.