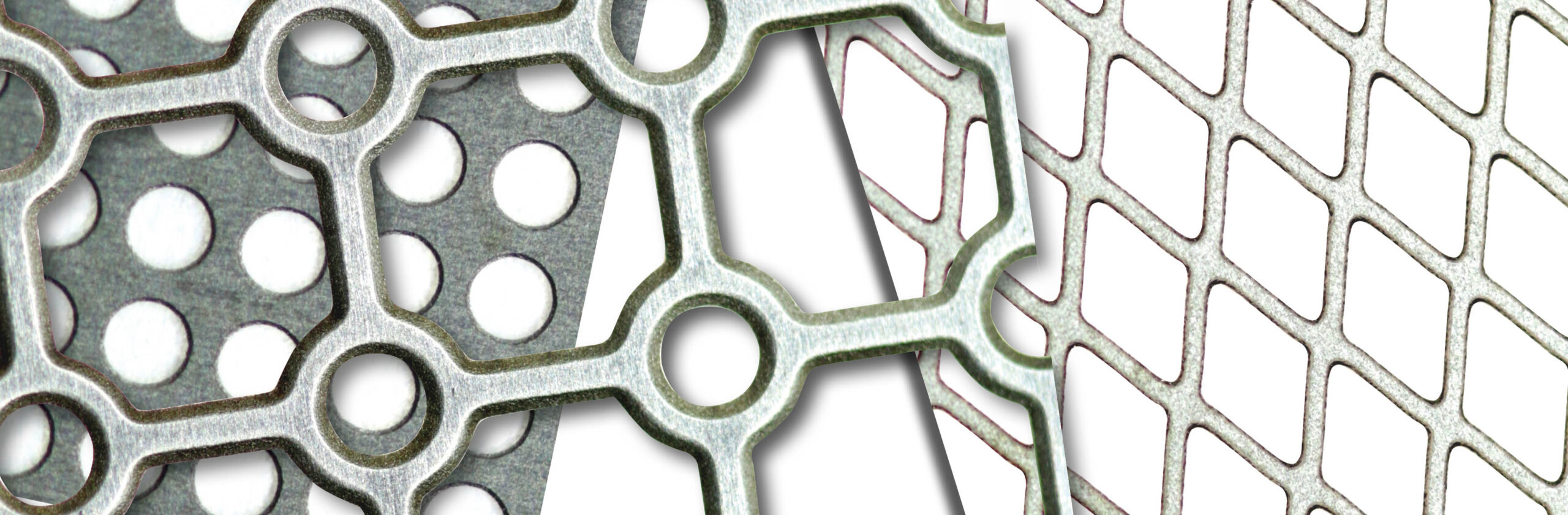

Precision etching in almost any metal

For more than four decades, Etchform has specialized in etching precision parts in almost any metal and alloy, including copper, brass, phosphor bronze, beryllium copper, many stainless steel alloys, and also special materials such as titanium, molybdenum, gold, nickel, and silver.

0.003 mm – 1.5 mm thickness

Applications are mainly for high-tech companies and can be found in high-tech machine construction, digital printing, electronics, optics, energy, medical, aerospace and automotive industries among many others

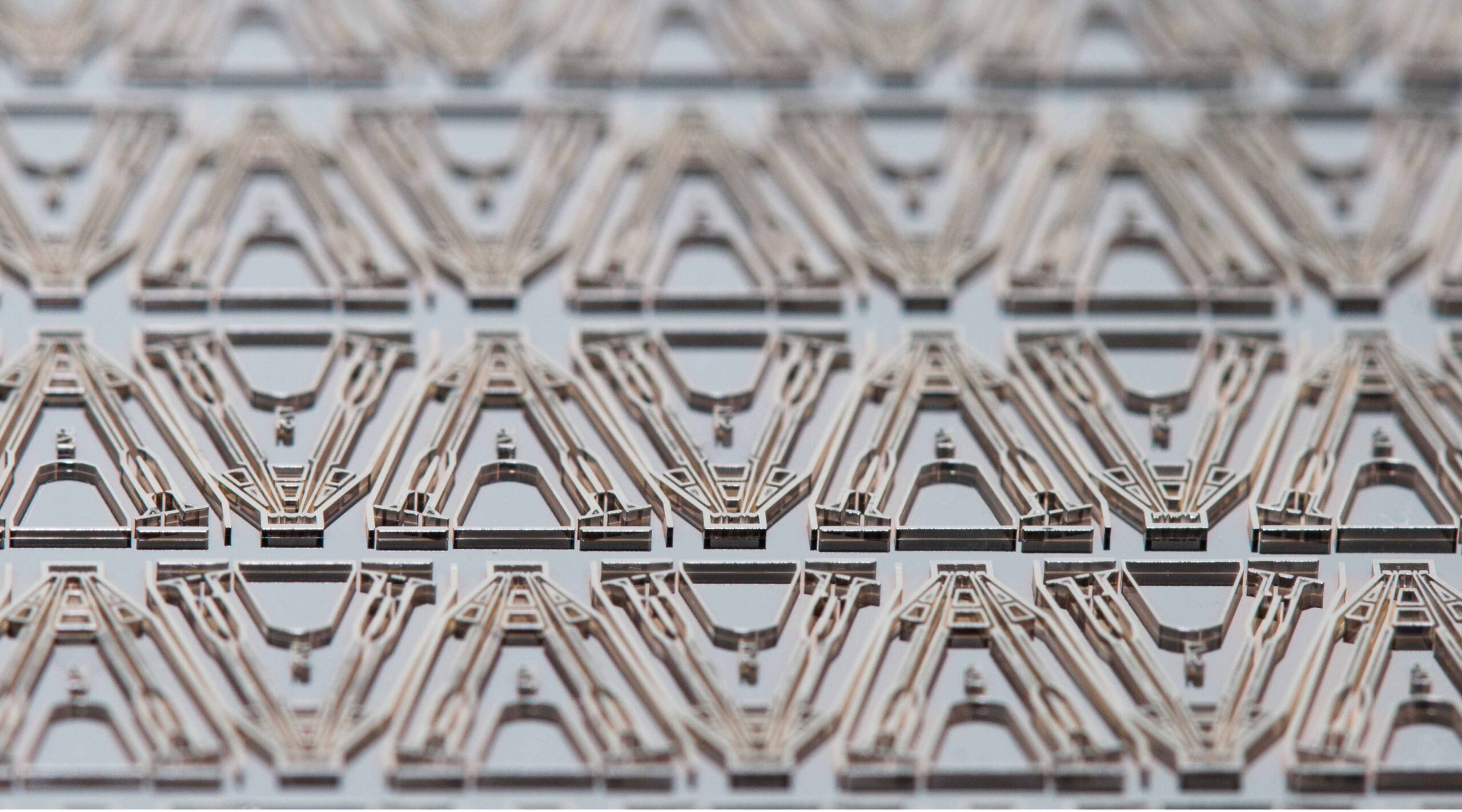

Electroforming

Etchform also offers precision parts produced by electroforming. Through the ability to make reliably accurate replicas on a mould surface — atom by atom — electroforming has become increasingly important in the production of metal parts on a micro- and nano-scale.

Up to 200 µm thickness

Soft or hard nickel

Complete services

Etched and electroformed parts often need one or more additional post-process treatments. These specialist treatments such as forming, fine mechanical/surface/heat treatment, laser welding/cutting, clean room packaging, or assembly are often outsourced, which means additional steps and complications in the supply chain.

With an established and strong partner network, Etchform can offer you a Full Service option: taking over the complete management of the supply chain and the responsibility to deliver you the final part required.