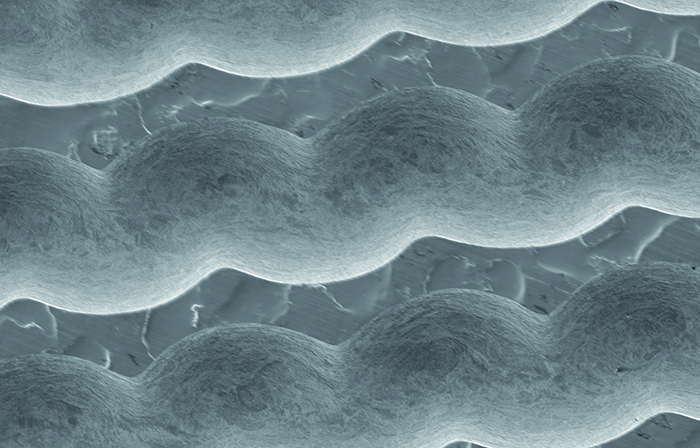

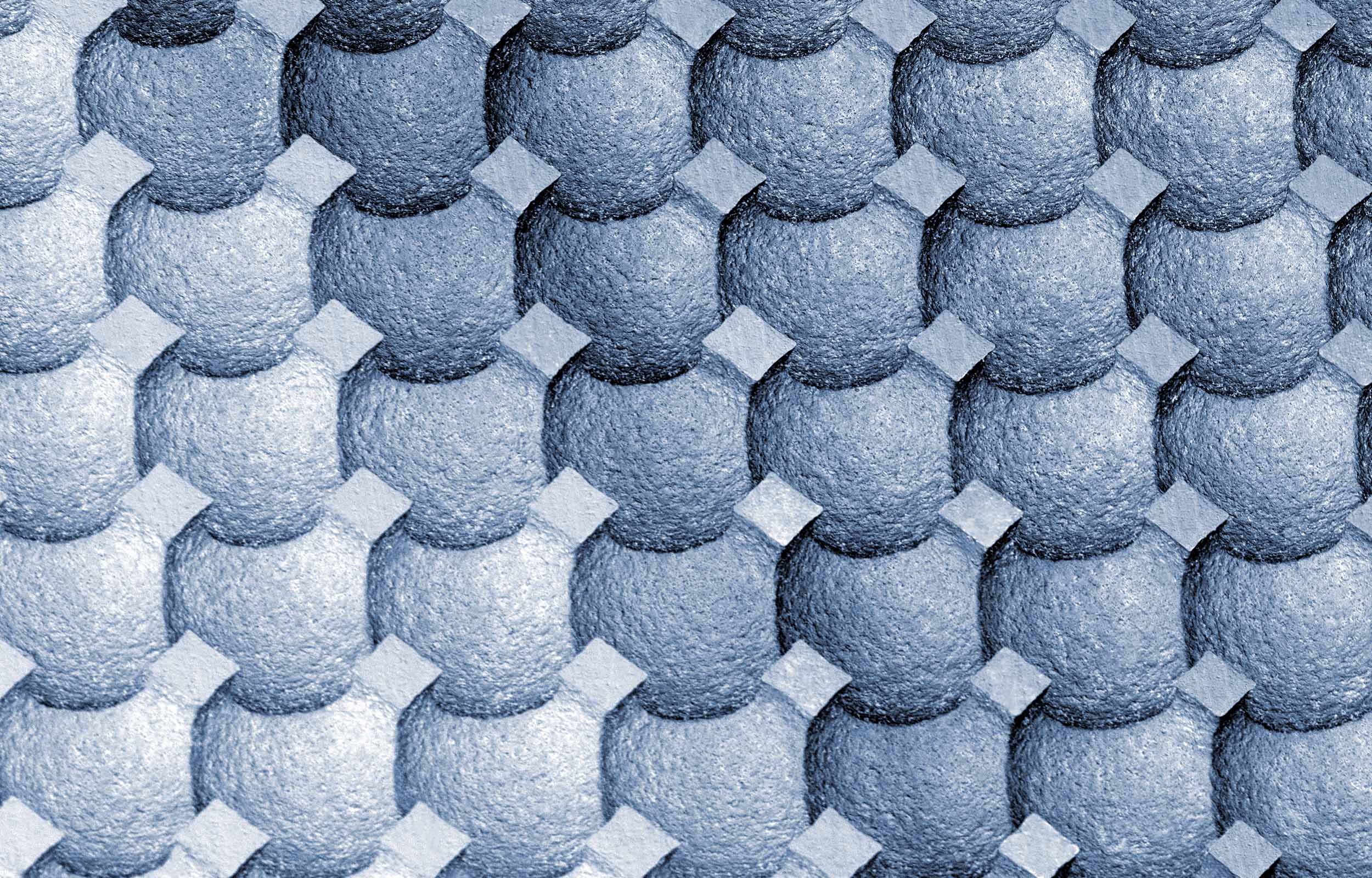

Chemically etched functional surfaces

In addition to producing desired geometries, micrometal's Etching Group is also able to process the surface of the parts. Your logo, a QR code or other engravings are only a small area of surface processing that is possible through the use of etching technology.

- Etching of the connecting webs to make the separation of the parts even easier

- Back-etching or special hole geometries in the edge area for a better hold during overmoulding or bonding

- Roughening of the surface for improved adhesion of e.g. brackets in the orthodontic field

Advantages at a glance

- Simple and safe post-processing

- Surfaces that cannot be achieved by other processes

- Surface finishing does not generate additional costs

- Very good flatness of the parts

- Large selection of metal types

Our standards are industry leading

We operate in a world characterized by the tightest tolerances (hundredths of a millimeter), the finest structures, the thinnest metals, and the most complex geometries. We etch customized metal components to the tightest tolerances in large-scale industrial production volumes.

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to ISO 9001, IATF 16949, and ISO 14001.