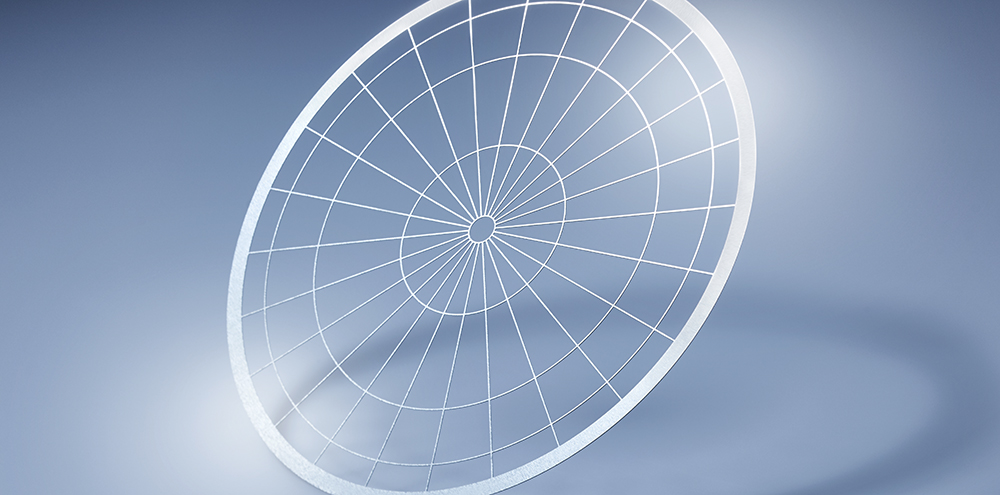

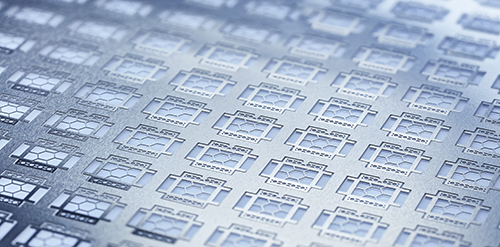

Fast and cost-effective batch etching

HP Etch — a subsidiary of Micrometal — is located 20 km west of Stockholm and has specialized in high precision etching since 1982.

Batch etching technology is not only fast but is also highly efficient and cost-effective. Tooling costs are very low, with designs for photo-chemical masks being created digitally and very quickly. This means that prototype runs, small, and medium volumes can be etched speedily and cost effectively. Nickel, stainless steel, aluminum, copper, and copper alloys are among the materials that can be processed. Further focal points are forming technology and Parylene coating technology.

High-precision etching technology "made in Sweden”

› Tolerance achievement of +/- 0.01 mm

› Fast, with small series production within one week

› Can process stainless steels and other steel alloys, iron-nickel alloys, copper alloys, aluminum, etc.

› ISO 9001 and ISO 14001

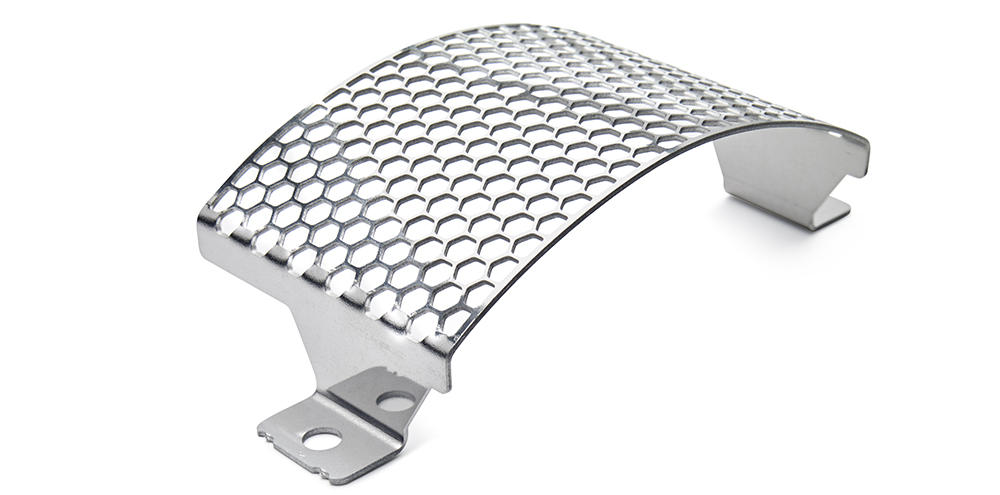

Forming technology for complex 3D parts

When HP Etch started the production of chemically etched thin metal parts it was clear that customers also required add-on services like bending..

Over the last 25 years, HP Etch has acquired the necessary knowledge and equipment for bending, and has been developing and fine tuning the production process to become a reliable partner for all existing and new customers.

Today HP Etch´s bending equipment consists of high-quality Press Brakes from leading manufacturers alongside smaller hydraulic presses. Hand forming is also possible in certain projects as a quick and cost-effective solution using blanks with half-etch bending lines.

Paratech Coating

The high-quality protective coating process known as Parylene protects electronic, electrical, and other sensitive products from environmental influences, especially when exposed to high stresses.

Summary of advantages: uniform and dense (pinhole free), stress-free, elastic, dielectric strength (200 V / µm), wear-resistant, biocompatible, fungus and bacteria resistant, radiation resistant, resistant to high and low temperatures (-200°C to + 200°C), and RoHS compliant.