Bending/forming Equipment

When HP Etch started the production of chemically etched thin metal parts it was clear that customers also required add-on services like bending.

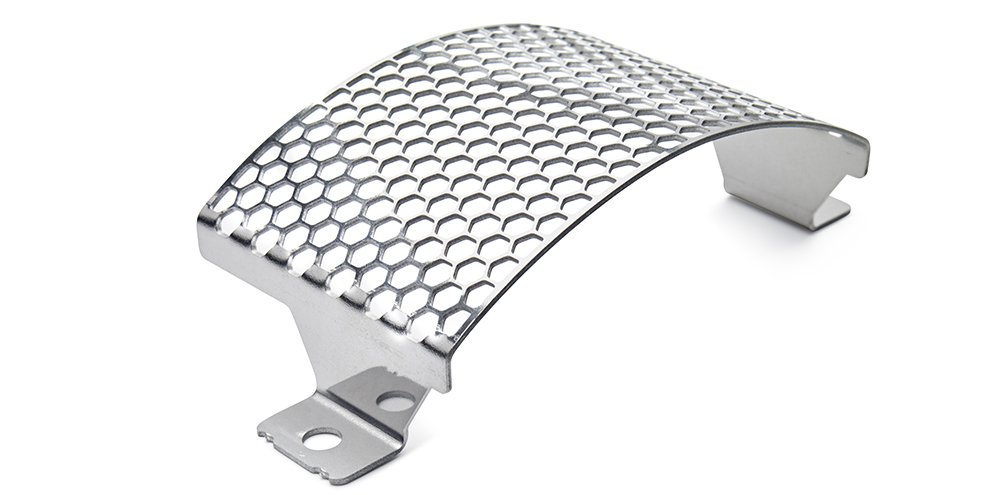

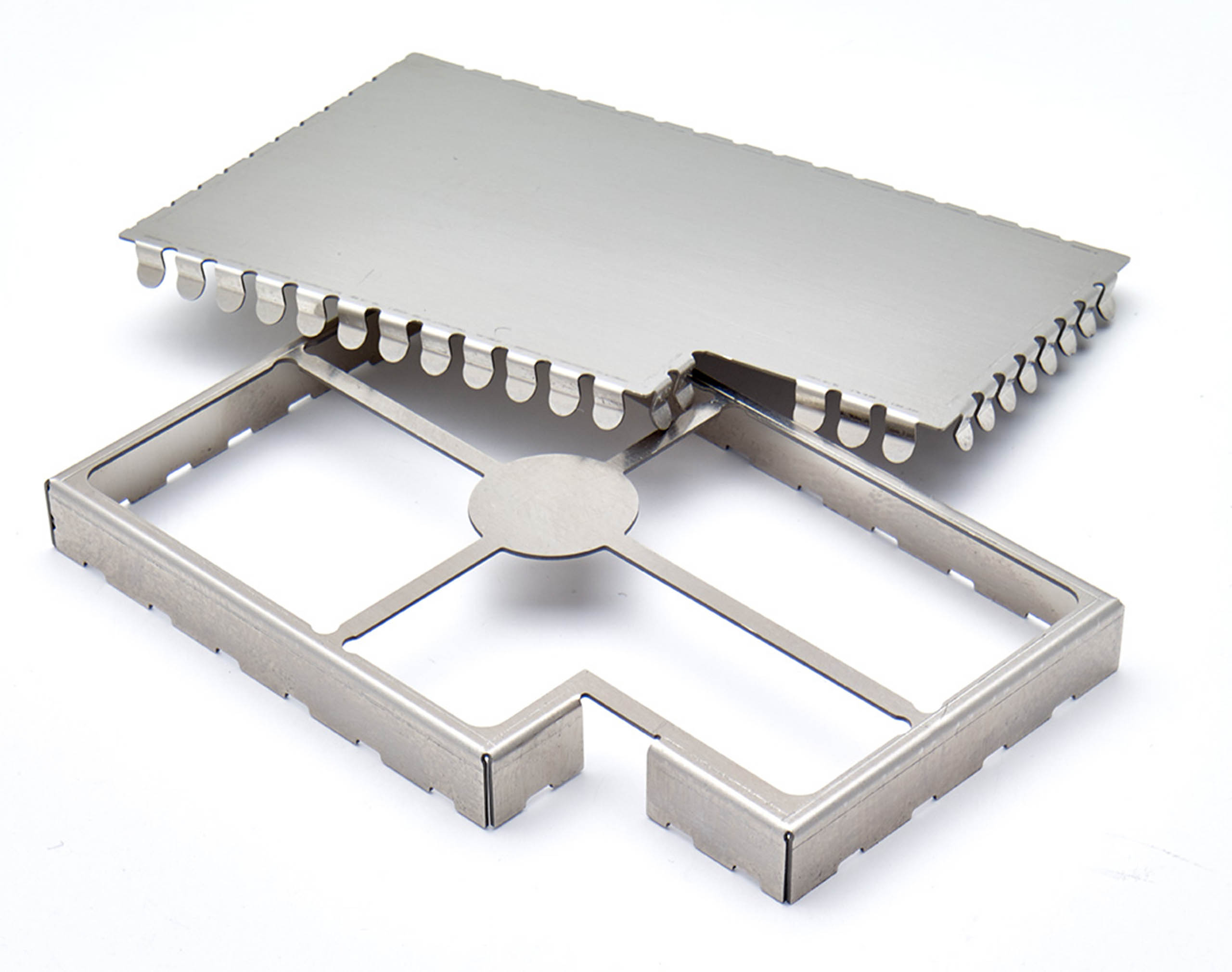

Our target was to become a high-quality bending supplier with a focus on thin parts up to 1 mm thick. Over the last 25 years, HP Etch has acquired the necessary knowledge and equipment for bending, and has been developing and fine tuning the production process to become a reliable partner for all existing and new customers.

Today HP Etch´s bending equipment consists of high-quality Press Brakes from leading manufacturers alongside smaller hydraulic presses. Hand forming is also possible in certain projects as a quick and cost-effective solution using blanks with half-etch bending lines.

Advantages

• We offer customers help when designing EMC/EMI shielding’s.

• “One stop shop”. We both etch and bend the parts in the same production site.

• High quality Press Brakes and skilled staff ensure tight tolerances.

• We supply both prototypes and high-volume production runs.

• With the knowledge gained from etching thin metal parts and the additional focus on bending, HP Etch has a profound understanding of customer demands and can contribute in all stages of the product development process life cycle.