Advantages of etched stencils

- No burrs or sharp edges

- Openings with rounded corners

- We can step etch to different thicknesses on the same stencil even on both sides

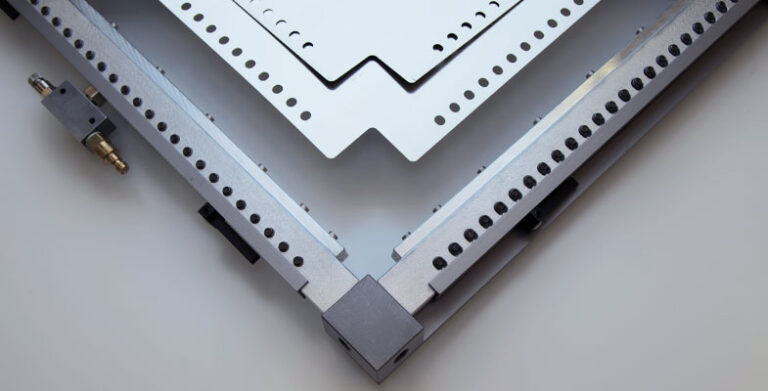

- Stress relief makes it easier to assemble and significantly improves the life of both stencil and tension frame.

We manufacture stencils for all tension frames and glued in frames eg. LPKF (Zelflex), ASM-DEK(VectorGuard), LTC (Quattro-Flex), Tecan (Genesis).

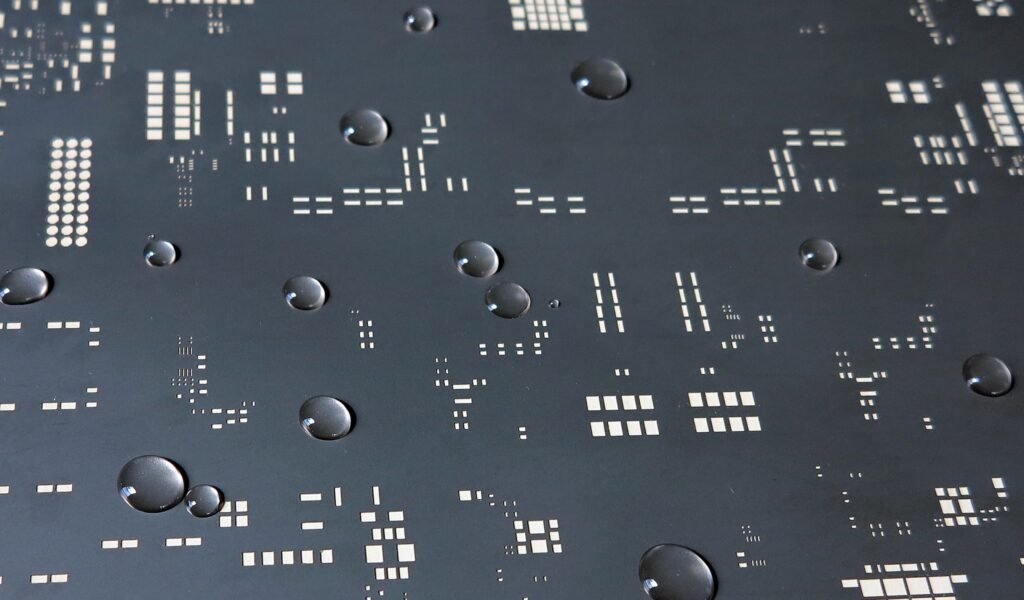

Stencil surface treatment

We can coat stencils with MicroShield or Nickel / PTFE (Teflon) for better paste release, less need for cleaning, and to reduce the risk of bridges..

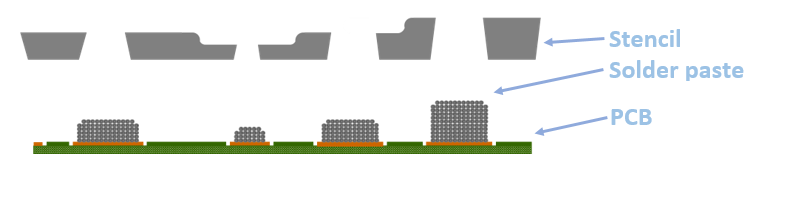

Stepped stencils

HP Etch is able to make apertures for components with pitch down to 0.25 mm.

We manufacture in standard thicknesses:

0.08, 0.10, 0.11, 0.12, 0.13, 0.15, 0.18, 0.20 and 0,25mm, and if required we can process thinner thicknesses.

We can step etch to different thicknesses on the same stencil even on both sides.

We have in-depth technical knowledge and extensive experience in the industry.

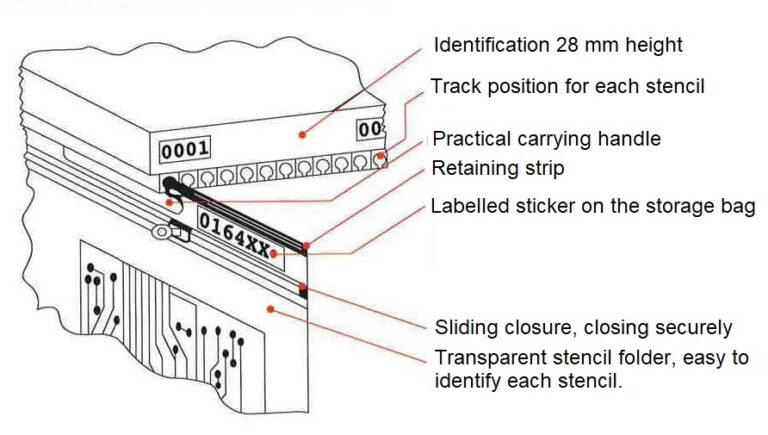

Storage / Advantages

- Safe and dust-free storage

- Transparent stencil folder

- Easy to identify each stencil

- Easy handling

- Large storage capacity

- Optimal archiving and little space requirement

- Superior price performance

- Excellent price-performance ratio

HP Etch AB

Patric Karmgård

Account Manager

Stencils/ ParaTech Coating