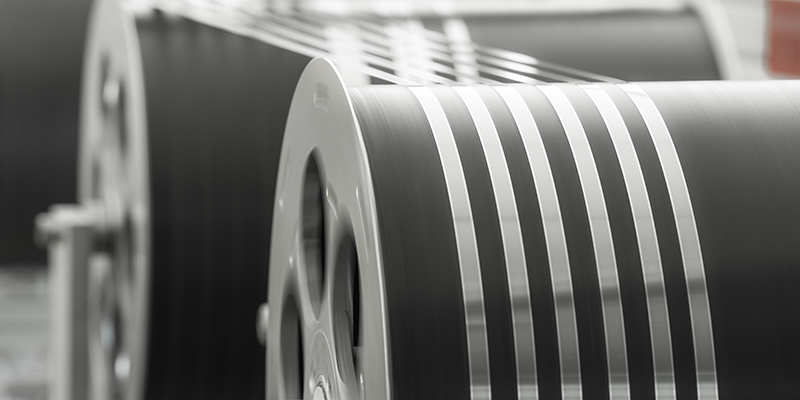

Reel-to-Reel Etching

The continuous reel-to-reel production line operated by micrometal allows the production of continuous etched, metallic strips. The production process is characterized by excellent reproducibility and the attainment of very tight tolerances, producing the finest structures and contours out of thin metal sheet. This unique etching process, therefore, guarantees individual customer solutions on an industrial scale.

Simple industrial processing

The metal strips, which can be up to 800 meters long on spools, are particularly popular in industries that already have a high degree of automation in further processing. For example, the etched parts can be selectively coated, or used by "pick & place" at the final point of use, processes that are popular in the medical technology and automotive industries.

Precise metal parts in an endless belt

The reel-to-reel etching process enables the production of thin metal parts in a continuous strip. The etched parts wound on spools can be separated when further processed at the customer's site, or fed to the next processing step by cutting to a pre-defined length. The thickness of the metal strip to be processed can be between 25 µm and 400 µm.