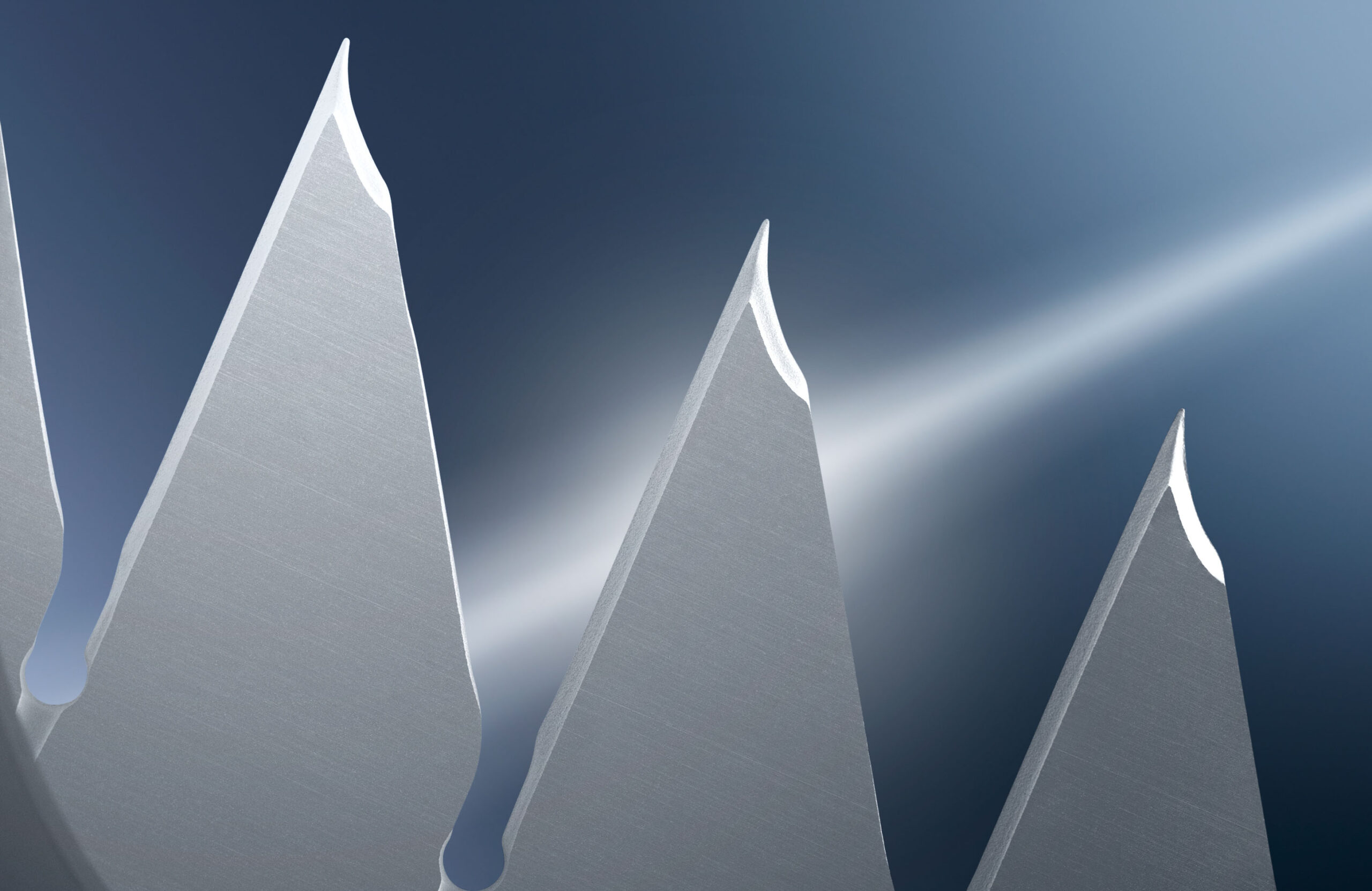

Needles

Medical devices are being made today requiring greater precision and increased complexity. The photo-chemical etching process is used for the manufacture of a variety of needles for medical applications. The photo tooling used in PCE can be changed cost-effectively, and so engineers have the design freedom to try multiple iterations in order to optimise and innovate ground-breaking geometries. micrometal developed its photo-chemical etching technology to allow for the exact control of the etching process in 3 dimensions. In addition, the fact that the process produces burr- and stress-free parts means that it is ideally suited to the production of micro needles, which can also be manufactured with innovative tip features and excellent tolerance control.

Advantages at a glance

- Multiple features in one part at no extra cost

- Can be applied to titanium

- Burr free, stress free, clean and flat parts

- Cost-effective tool production/design iterations

- Realization of complex designs (channel structures)

Standards und Kompetenzen

micrometal verfügt über jahrzehntelange Erfahrungen mit den höchsten Standards, die Hersteller von Medizinprodukten fordern. Daher sehen wir uns als ersten Ansprechpartner, wenn es um die Zusammenarbeit mit einem qualifizierten Fertigungsdienstleister geht.

Wir adaptieren ständig den bewährten Ätzprozess auf ein wachsendes Portfolio von medizinischen Metalllegierungen und verfügen über eine der größten Ätzproduktionskapazität der Welt. Darüber hinaus bietet das Unternehmen weltweiten technischen Support und eine Reihe von ergänzenden Technologien an, die sicherstellen, dass die hohen Genauigkeitsanforderungen, die in der Medizintechnik gelten, stets erfüllt werden.

Wir können mit Stolz verkünden: micrometal ist seit dem 27.10.2023 nach ISO 13485 zertifiziert .

Die internationale Norm EN ISO 13485 ist der Standard für Qualitätsmanagementsysteme im Medizinproduktebereich

Mit dem Erhalt der ISO-Zertifizierung 13485 für medizinische Produkte garantiert micrometal höchste Qualität und Sicherheit bei der Herstellung Ihrer Ätzkomponenten. Die Erfahrung von micrometal in der Zusammenarbeit mit Kunden in der Medizintechnik garantiert einen vollständigen Fokus auf die einzigartigen regulatorischen und Standardisierungsanforderungen der Medizintechnik.

Das Unternehmen ist zudem nach ISO 14001, ISO 9001 und IATF 16949 zertifiziert.