Cooperation with ifw Jena

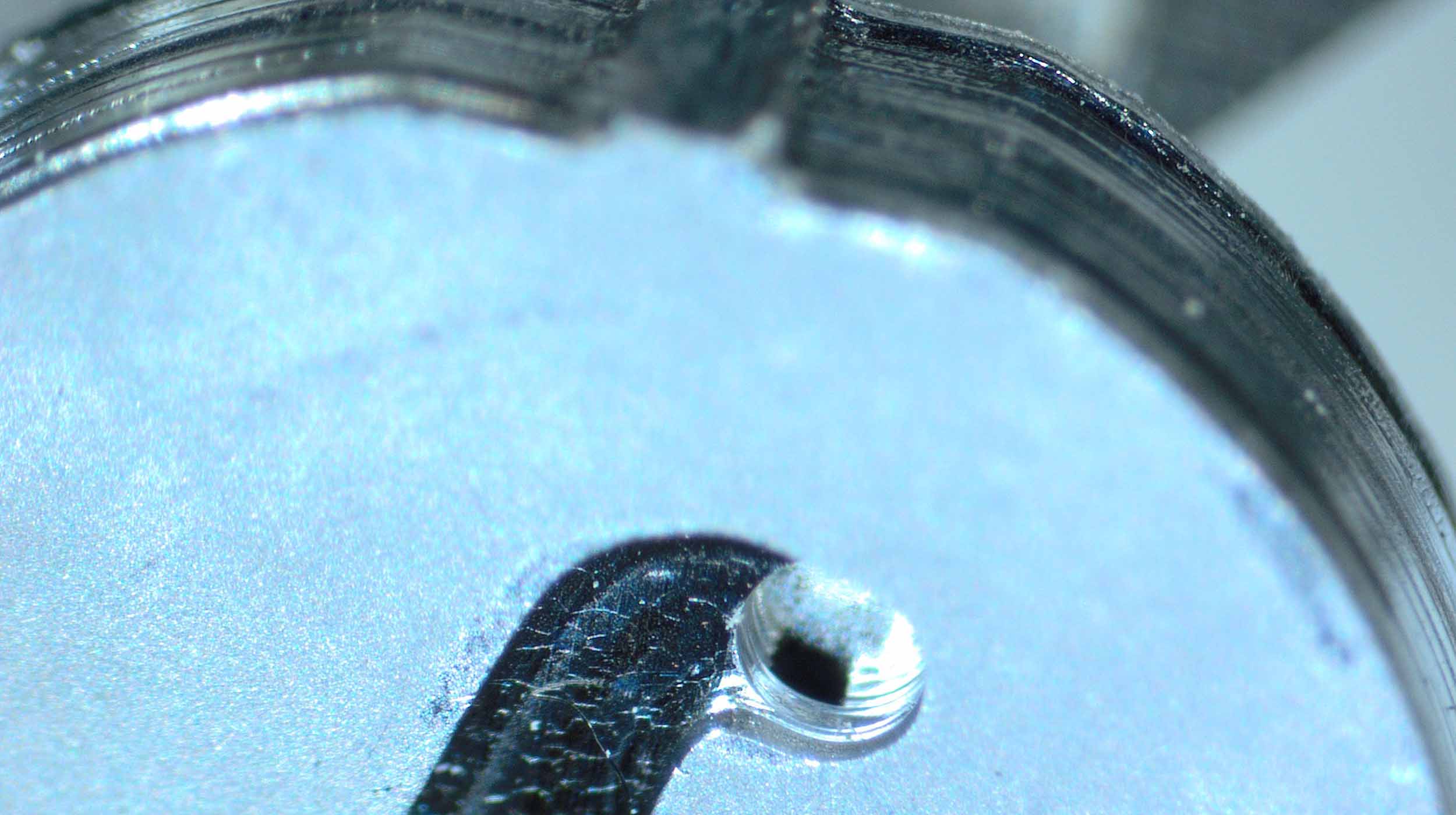

Diffusion welding is increasingly proving to be an innovative solution when it comes to large-area, pressure-resistant, and vacuum-tight welded joints with a requiring a long service life and high durability. Diffusion welding can be used to produce monolithic components or semi-finished products that are composed of several layers or of molded part halves. Under the influence of pressure and heat, the individual layers are welded together over their entire surface in a single welding process. No filler material or interlayer work is required. In this way, complex hollow structures can be created inside the component that cannot be produced by established metal-cutting manufacturing processes. With its experience and modern technical equipment, the ifw Jena Institute is a long-standing partner for regional and international companies and research institutions.

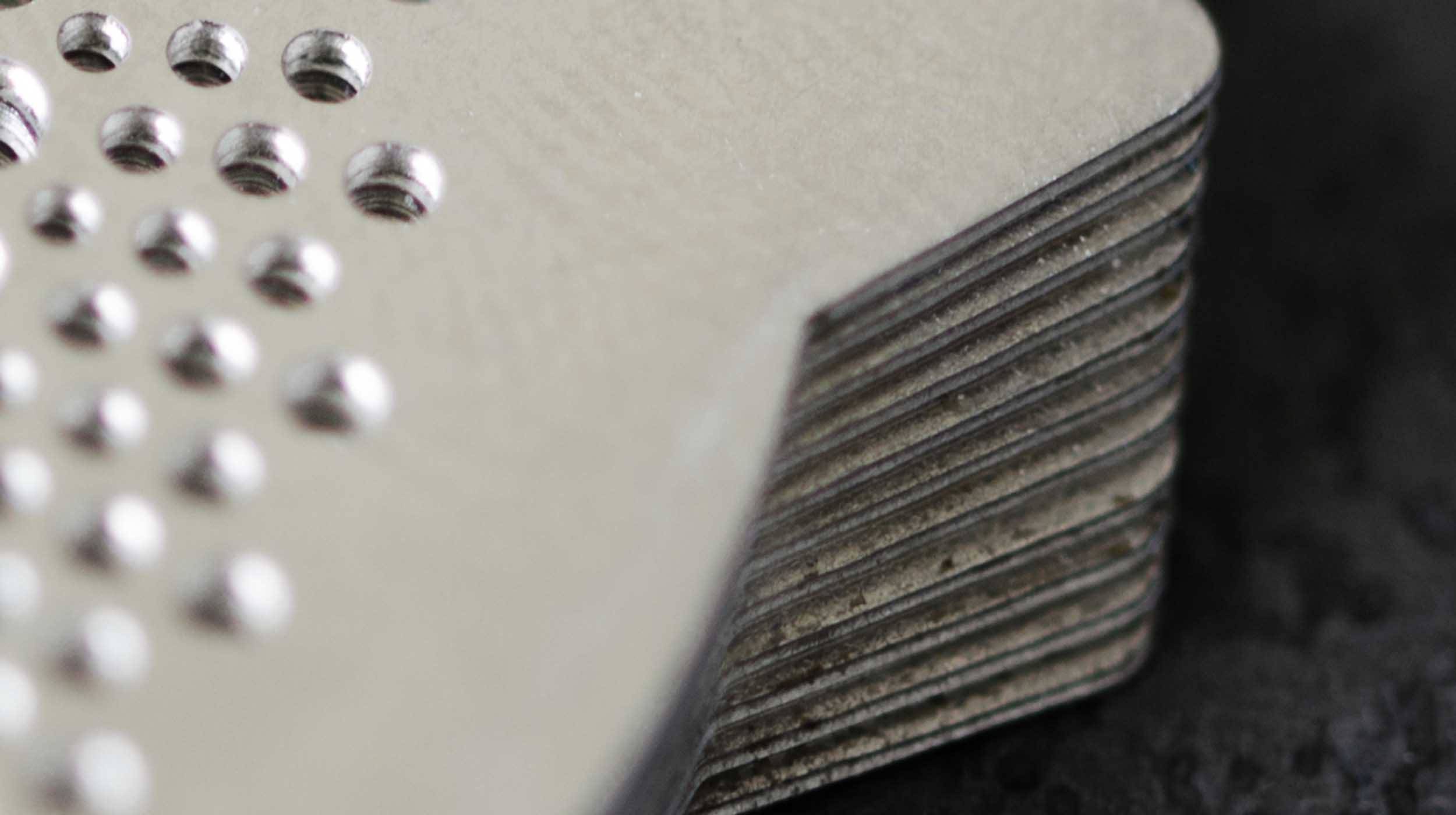

ifw Jena cooperates with micrometal GmbH in the field of diffusion bonding, and applies the process to etched precision foils. Foil thicknesses of less than one 500 micrometers enables the production of particularly complex structures inside the component. In this way, precise miniature components are produced that are used in high-frequency and power electronics and microfluidics, among many other applications.

In addition to diffusion bonding, the services and research work of ifw Jena — Günter-Köhler-Institut für Fügetechnik und Werkstoffprüfung GmbH — is concerned with laser material processing, additive manufacturing, and other furnace-based processes. Likewise, ifw Jena develops bonding technologies with organic and inorganic adhesives for high-temperature applications as well as innovative welding processes with arc and laser welding technologies.