micrometal at the Stanztec 2024

Stanztec, the trade fair for the stamping technology will take place in Pforzheim from 25 to 27 June 2024. We look forward to your visit (Hall KS, Stand D11).

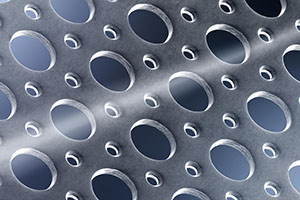

Photo-chemical etching of filters for effective light and sound management

How the characteristics of micrometal’s etching process allow for the manufacture of very thin metal filters …

Quality in photo-chemical etching (eng)

Quality issues are of paramount importance in photo chemical etching (PCE) because the precision of the etching process directly affects the final product’s accuracy and reliability.

Etching for Electric Vehicles & Sustainability (eng)

It is well-known today that photo-chemical etching (PCE) is a precise and cost-efficient way to fabricate complex parts with intricate geometries, tight tolerances, and highly repeatable results for large production runs. However, what is less well known is how this technology is evolving, and also what this evolution means for the stimulation of design freedom.

PCE stimulates design opportunities (eng)

It is well-known today that photo-chemical etching (PCE) is a precise and cost-efficient way to fabricate complex parts with intricate geometries, tight tolerances, and highly repeatable results for large production runs. However, what is less well known is how this technology is evolving, and also what this evolution means for the stimulation of design freedom.

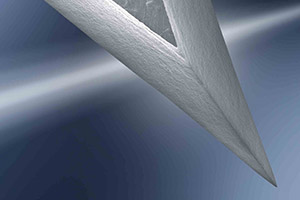

Photo-chemical ETCHING making an opthalmic blade

micrometal, is pleased to be able to demonstrate the power of its next generation precision metal processing technology following some recent work with a manufacturer of opthalmic devices incorporating surgical blades.

Etching Group auf der Hannover Messe 2023 (eng)

The micrometal Group exhibited at the Hannover Show April 17-21. The company demonstrated to visitors that it offers the next generation photo-chemical etching (PCE) process which is orders of magnitude more precise and repeatable than any other PCE process on the market.

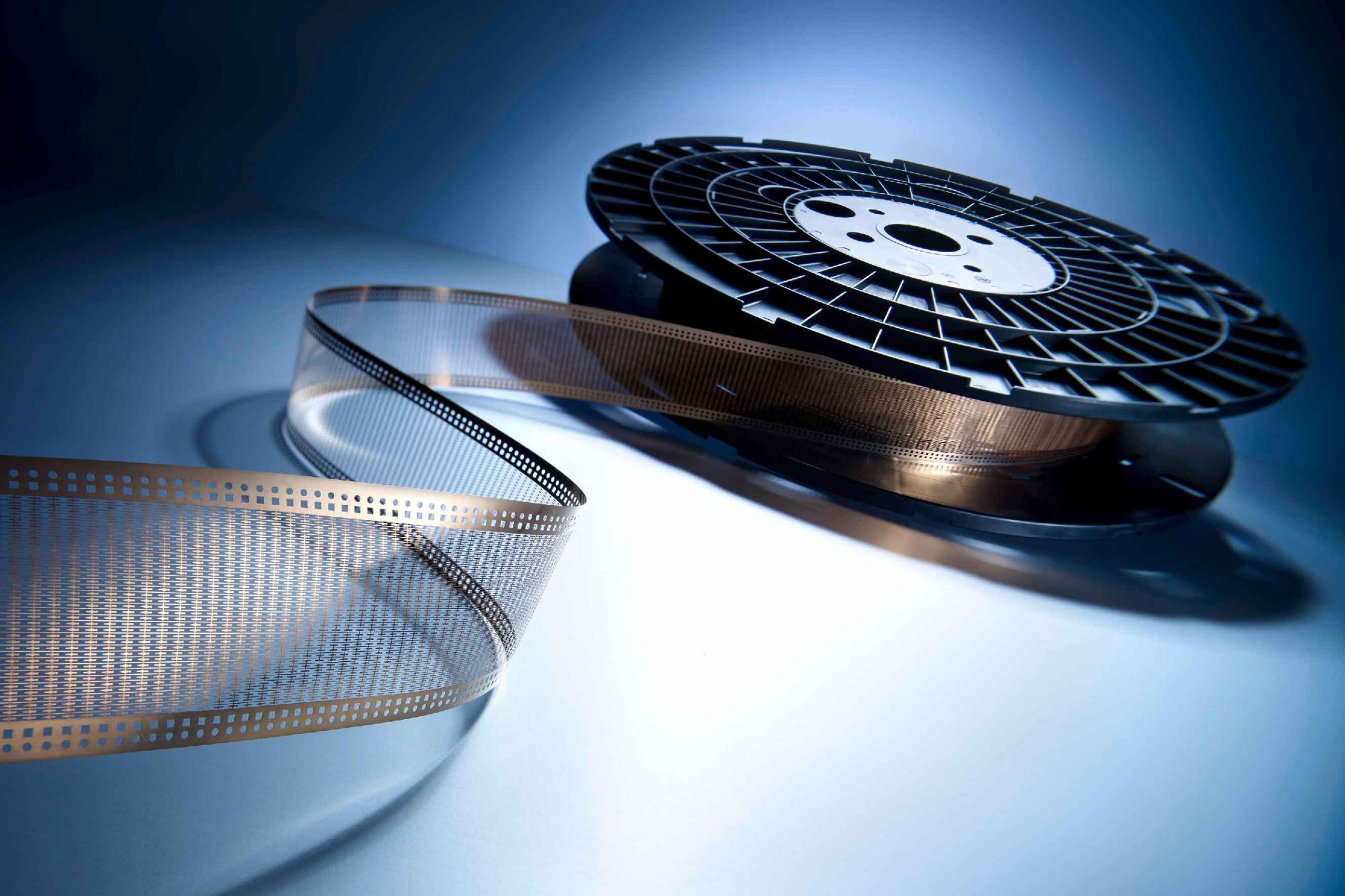

PCE making lead frames (eng)

The micrometal Group has developed a next-generation photo-chemical etching (PCE) process which is ideally suited to lead frame production.

New White Paper

micrometal GmbH is at the forefront of the evolution the photo-chemical etching (PCE) process, and today announces the availability of a new White Paper entitled “Unlocking the True Potential of Precision Metal Fabrication”.

Ten things you need to know

What do you consider to be the key attributes of PCE? What do design engineers need to know about the materials that PCE can be used with?