Etching Group = Micro Component Group

The Micro Component Group brings together four industry leaders in precision photo-chemical etching: micrometal GmbH, HP Etch AB, Etchform BV, and Thin Metal Parts Inc..

As a collective, we offer one of the world’s most comprehensive and agile platforms for manufacturing ultra-precise metal components. Covering everything from reel-to-reel high-volume etching to batch-based prototyping and specialty applications.

Each company within the Micro Component Group contributes distinct technical capabilities, regional proximity, and decades of experience in serving demanding industries such as medical, aerospace, semiconductor, and automotive.

Our operations span locations in Muellheim (Germany), Jaerfalla (Sweden), Hilversum (The Netherlands), and Colorado Springs (USA), and are backed by our parent company Wickeder Group, providing both financial stability and long-term strategic support.

With more than 180 specialists across Europe and North America, we combine global reach with local presence — ensuring you always have expert support within easy reach.

The Micro Component Group: delivering innovation, scale, and precision without compromise.

Micrometal

micrometal was founded in 2006 in Müllheim, Baden, Germany, and is considered the inventor of the fully cross-linked INLINE etching technology. This is a highly automated and continuous manufacturing process that guarantees the highest degree of repeatability, process stability, and economic efficiency.

By means of Reel-to-Reel Inline lithography, a wide variety of geometrically demanding structures can be created. Our in-house developed mask technology also enables the control of the etching process in the 3rd dimension. This means that specific breakthrough geometries can also be produced, with a symmetrical or asymmetrical cross-sectional area depending on the exposure and etching parameters. This enables micrometal to produce complex geometries for medical products such as lancets, scalpels, and blades on a large scale.

Etchform

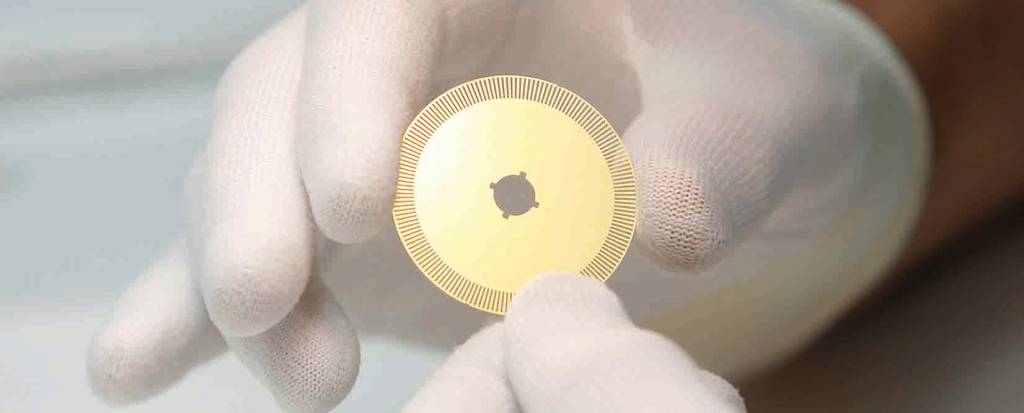

Etchform was founded in 1980 in Hilversum, the Netherlands, and supplies complete and customised solutions for thin precision parts in almost all metals, based on etching technology and electroforming.

In addition, Etchform's offerings also include forming, precision mechanical/surface/heat treatments, laser operations, assembly, and clean room packaging. This allows our customers to focus on their core competencies.

HP Etch

HP Etch from Stockholm, Sweden has specialised in high-precision etching of thin metals since 1982. Vertical integration and the large selection of materials in stock enables rapid delivery from prototypes to large series.

Bending and forming technology — based on CNC-controlled machines — are part of the extensive range of solutions, as are special coating technologies.

Parylene coating technology (polymer coating) in particular is used for products that are exposed to extreme conditions and environmental influences, for example in the electronics, aerospace, medical, and mechanical engineering industries.