High-precision etching technology "made in Sweden”

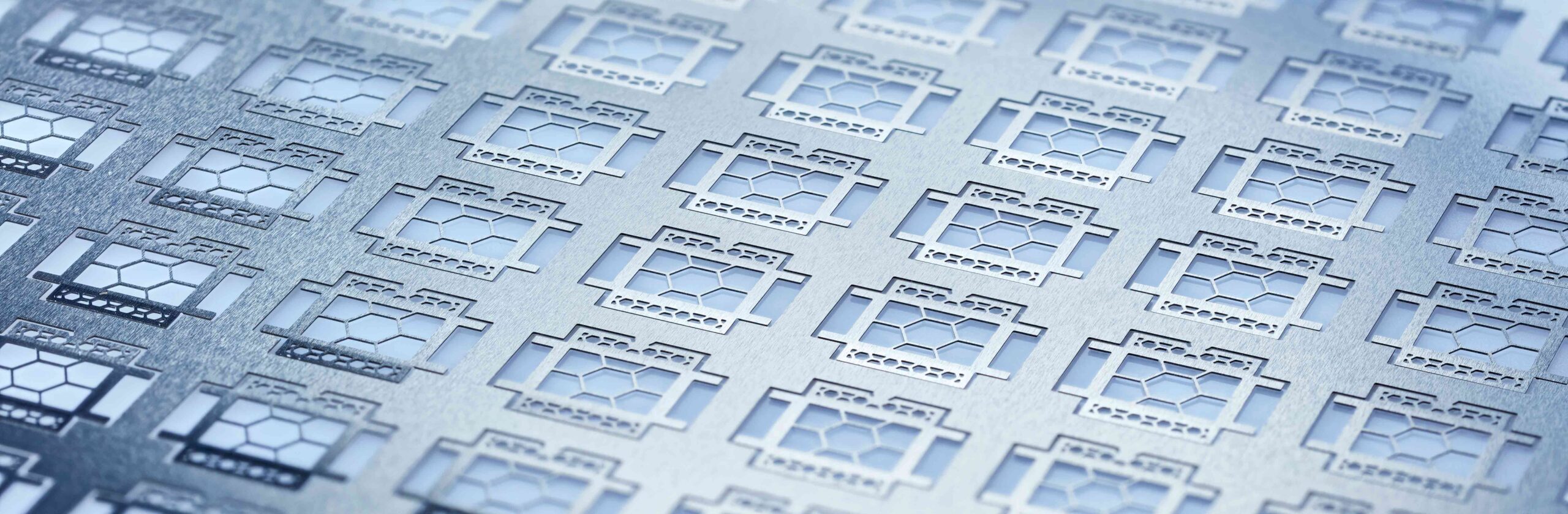

HP Etch batch etching technology is not only fast but also effective and cost-efficient. Tooling costs are very low and designs for photo-chemical etching masks are created digitally within a very short period of time. This allows prototypes, small, and medium quantities to be etched quickly and cost-effectively. Nickel, stainless steel, aluminum, copper, and copper alloys are among the materials processed.

› High precision with tolerances up to +/- 0.01 mm.

› Fast, small batches within one week

› Stainless steels and other steel alloys, iron-nickel alloys, copper alloys, aluminum, etc.

High-precision etching technology "made in Holland”

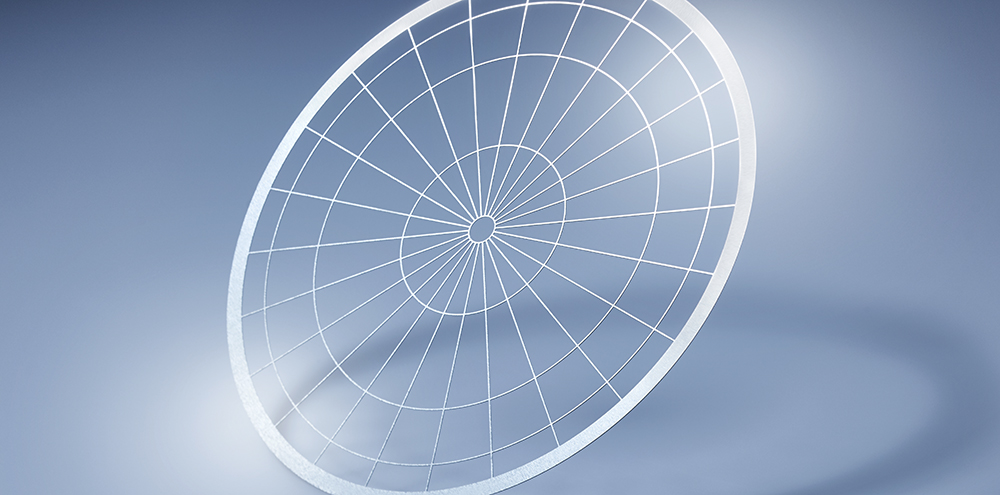

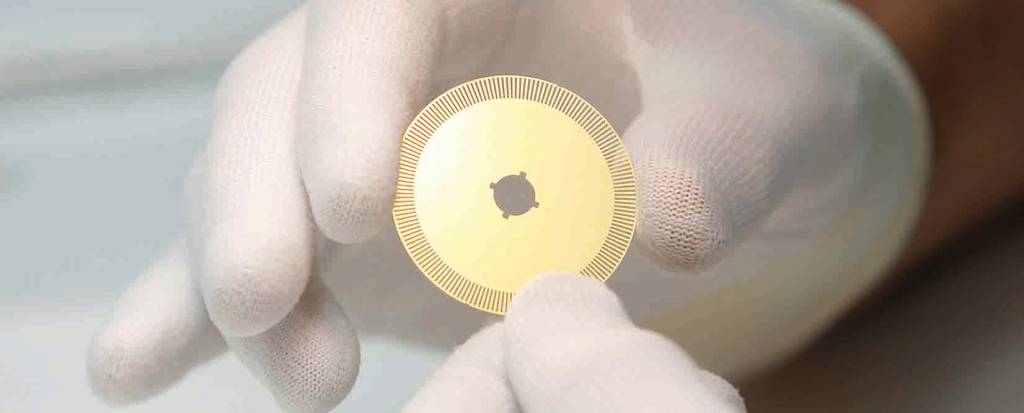

Etchform provides complete and customized solutions for thin precision parts in almost all metals, based on etching techniques and electroforming. Among others, metals including copper, brass, phosphor bronze, beryllium copper, many stainless steel alloys, and also special materials like titanium, nitinol, molybdenum, gold, nickel, and silver can be processed.

Etchform offers a wide range of processes such as electroforming, heat & surface treatment, laser operations, clean room packaging, and chain management and has a strong network of partners meaning that customers can focus on their core expertise.

Production by cutting or etching from metal plates for smaller quantities or for manual processing is also available.